Introduction to Waste to Biomass Energy in Home

- Converting waste from surrounding into biomass energy is called as waste-to-energy (WTE)

- It involves a series of processes to extract energy from organic waste materials.

- Waste can be converted to biomass solids . Later it can be used for Biomass gasification or pyrolysis to produce energy in your home to save cost .

Advantage of Waste to Biomass Energy in Home

- Sustainable Energy Source:

- Waste-to-biomass energy provides homeowners with a sustainable and renewable source of energy.

- Biomass feedstock, such as wood pellets or agricultural residues, can be locally sourced and replenished, reducing reliance on fossil fuels.

- Energy Cost Savings:

- By using waste materials or locally available biomass as a fuel source

- homeowners can potentially reduce their energy costs compared to relying solely on electricity, natural gas, or heating oil. These waste can be used for biofuels.

- Reduction in Waste Disposal Costs:

- Converting certain types of organic waste into biomass energy can help homeowners reduce waste disposal costs.

- For example, using a wood pellet stove can consume wood waste that might otherwise be sent to landfills or require disposal fees.

- Carbon Neutrality:

- Biomass energy is considered carbon-neutral because the carbon dioxide (CO2) released during combustion

- It is offset by the CO2 absorbed by the plants during their growth.

- This helps mitigate the carbon footprint associated with home energy use.

- Diversification of Energy Sources:

- Using waste-to-biomass energy at home diversifies the sources of energy available to homeowners,

- By enhancing energy security and reducing vulnerability to fluctuations in fossil fuel prices.

- Reduced Environmental Impact:

- Biomass energy tends to have lower emissions of sulfur and nitrogen compounds compared to some fossil fuels, contributing to improved air quality.

- Waste-to-biomass energy can also reduce the environmental impact of waste disposal, as it prevents the release of methane from landfills.

- Local Economic Benefits:

- Supporting local biomass industries and suppliers can have positive economic effects on the community by creating jobs and stimulating local economies.

- Energy Independence:

- Producing biomass energy at home can promote a sense of energy independence, giving homeowners greater control over their energy supply.

- Resilience:

- Biomass energy systems, such as wood stoves or pellet heaters,

- It can serve as backup heating sources during power outages, enhancing the resilience of homes in extreme weather conditions.

- Rural and Off-Grid Solutions:

- Biomass energy is particularly valuable for homes in rural or off-grid areas where access to traditional energy sources may be limited or costly.

Steps in waste to energy conversion

- Collection of waste

- Drying of Biomass

- preparation of biomass for burning in a stove

- transportation

- Burning or combustion in stove

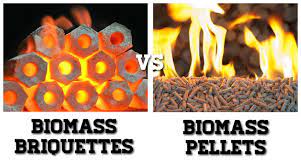

Converting Biomass Waste to briquette or Pellets

- Converting biomass waste into briquettes or pellets is an efficient and sustainable way to utilize organic materials for energy production or other applications.

- Both briquettes and pellets are densified forms of biomass that are easier to handle, transport, and store compared to loose biomass materials.

- Here’s how to convert biomass waste into briquettes or pellets:

Collect and Prepare Biomass Waste:

- Gather biomass waste materials such as sawdust, wood chips, crop residues, agricultural waste, or other organic waste suitable for briquetting or pelletizing.

- Ensure that the waste materials are clean and free from contaminants such as stones, plastic, or metal.

Size Reduction:

- Reduce the size of the biomass waste to make it more suitable for the briquetting or pelletizing process. This can be done using a chipper, shredder, or hammer mill.

- The size reduction process aims to create smaller, uniform particles with a size suitable for densification.

Drying of Biomass

- Biomass materials often contain moisture, which can hinder the densification process. Properly drying the biomass waste is essential.

- Use a biomass dryer or natural sun drying to reduce the moisture content to the optimal level, typically below 10% for briquettes and 15% for pellets.

Briquette and Pellet Production:

- Both biomass briquettes and pellets offer advantages in terms of energy density, ease of handling, and storage, making them valuable options for converting biomass waste into a valuable energy resource or other commercial products.

- The choice between briquettes and pellets depends on specific applications and equipment requirements

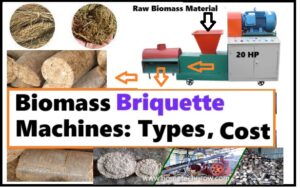

For Briquettes

- Mix the dried biomass waste with a binder material, which is usually a natural adhesive like starch or a commercial binding agent.

- The binder helps hold the briquettes together during compression.

- Feed the mixture into a briquette press or extruder machine.

- These biomass briquette machines compress the mixture under high pressure to form briquettes with the desired shape and density.

- Depending on the desired briquette shape, use appropriate molds or dies within the machine to achieve the desired shapes like, cylindrical, square, or custom shapes).

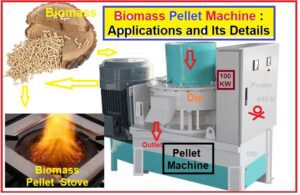

Pellet Production:

-

- There are many pelletizing machines (pellet mills) which are used to produce biomass pellets.

- The dried biomass waste is pulverized and then it is typically fed into the pellet mill.

- In this pellet makin machine it is compressed and extruded through a die with small holes to form cylindrical pellets.

- Pellets are typically smaller and more uniform in size compared to briquettes.

Cooling and Solidifying:

- Allow the freshly formed briquettes or pellets to cool and solidify. This may involve transferring them to a cooling rack or chamber.

- Cooling helps the densified biomass harden and maintain its shape.

Packaging and Storage:

- Once cooled and solidified, package the briquettes or pellets in bags or containers suitable for transportation and storage.

- Store the densified biomass in a dry, cool, and well-ventilated area to prevent moisture absorption and deterioration.

Quality Control:

- Conduct quality control checks to ensure that the briquettes or pellets meet the desired specifications in terms of size, density, and moisture content.

Utilization:

- Use the biomass briquettes or pellets as a clean and sustainable fuel source for various applications, such as heating, cooking, power generation, or as a feedstock for industrial processes.

- Ensure that the combustion or utilization equipment is suitable for the type of densified biomass produced (briquettes or pellets).

Waste Collection and Sorting:

- Collect various types of waste materials, including municipal solid waste (MSW), industrial waste, agricultural residues, and sewage sludge.

- Sort and prepare the waste to remove non-combustible materials, recyclables, hazardous substances, and contaminants. Proper waste sorting is crucial for the efficiency and safety of the conversion process.

- Waste collection and sorting are critical initial steps in the waste-to-biomass energy conversion process.

- Properly collecting and sorting waste materials ensure that the feedstock used in biomass energy production is suitable for efficient and environmentally responsible conversion.

- Here’s how waste collection and sorting are typically done for biomass energy:

Waste Collection:

- Municipal Solid Waste (MSW):

- For municipal waste streams, such as household garbage, waste collection is typically organized and managed by local authorities.

- Residents and businesses separate their waste into designated bins or containers, including recyclables and non-recyclables.

- Industrial Waste:

- Industrial waste is usually collected and managed by the generating industries.

- Companies often have specific waste management procedures to segregate hazardous and non-hazardous waste materials.

- Agricultural Residues:

- In agriculture, residues such as crop waste (e.g., corn stover, rice straw) are typically collected after the harvest season.

- Farmers or agricultural cooperatives may collect and store these residues for future use as biomass feedstock.

- Sewage Sludge:

- Sewage sludge is collected at wastewater treatment plants. It is the residue left behind after the treatment of sewage and wastewater.

- It can be processed and used as a biomass feedstock

Waste Sorting for Biomass

- Pre-Sorting:

- Before waste materials are sent to a waste-to-biomass energy facility, they often undergo pre-sorting at recycling centers or transfer stations.

- This involves separating recyclable materials (e.g., paper, cardboard, plastics, metals) from non-recyclable waste.

- Recyclables are diverted for recycling, reducing the amount of waste sent for energy conversion.

- Hazardous Waste:

- Hazardous waste materials are separated and managed separately according to specific regulations. These materials typically do not go to waste-to-energy facilities.

- Quality Control:

- For biomass energy production, it’s essential to maintain the quality of the feedstock.

- This involves removing contaminants and ensuring that the waste materials are suitable for combustion or gasification.

- Contaminants may include hazardous materials, large non-combustible items, and items that can damage equipment.

- Organic Fraction:

- The organic fraction of waste, which includes food waste and other biodegradable materials, is often separated for specialized treatment, such as anaerobic digestion or composting, to generate biogas or compost instead of direct combustion for energy.

Storage and Transportation:

- Sorted waste materials are typically stored at waste transfer stations or intermediate facilities before transport to the waste-to-biomass energy plant.

- The waste materials are then transported to the energy facility using appropriate vehicles, such as trucks or conveyor systems.

- Proper waste collection and sorting are crucial to ensuring the efficiency of biomass energy production and minimizing environmental impacts.

- By removing contaminants and non-combustible materials and separating recyclables, the waste stream is optimized for energy conversion, contributing to the sustainability and environmental responsibility of waste-to-biomass energy processes.

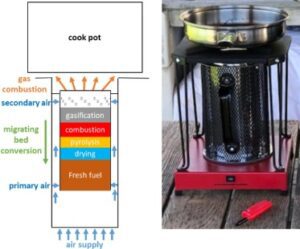

Combustion or Gasification of Biomass

- Choose between combustion or gasification as the primary conversion method, depending on the specific technology and objectives of the waste-to-biomass energy plant.

Biomass Pyrolysis

- Description: Pyrolysis is a thermal decomposition process that converts organic waste materials into a bio-oil, biochar, and syngas in the absence of oxygen.

- Bio-oil can be used as a biofuel, while biochar can be used as a soil amendment.

- Applicable Waste Types: Biomass, agricultural residues, and some types of plastics.

- Benefits: Yields valuable products like bio-oil and biochar, and can be more efficient than simple combustion.

Combustion:

- In combustion, waste materials are burned in a controlled environment, typically in a combustion chamber, to produce heat.

- The heat generated is used to generate steam, which drives a turbine connected to an electricity generator, producing electricity.

- Emissions from combustion, including ash and pollutants, must be controlled and treated to meet environmental regulations.

Gasification:

- In gasification, waste is heated in an oxygen-starved environment to produce a synthetic gas (syngas) consisting of carbon monoxide (CO) and hydrogen (H2).

- The syngas can be burned directly to produce heat or further processed to remove impurities before combustion.

- Gasification can also be used to produce biofuels or chemicals in addition to electricity.

Heat and Electricity Generation:

- Use the heat produced in the combustion or gasification process for various purposes, such as:

- District heating for nearby communities.

- Industrial processes that require high-temperature heat.

- In both combustion and gasification processes, steam generated by the heat is used to drive a steam turbine, which generates electricity.

Emissions Control and Environmental Compliance:

- Implement emissions control technologies to reduce the release of pollutants, including nitrogen oxides (NOx), sulfur dioxide (SO2), particulate matter, and dioxins.

- Meet environmental regulations and standards to minimize environmental impacts.

- Some technologies help ensure compliance with environmental regulations.

Ash and Residue Management:

-

- Ash and other residues are produced as byproducts of the combustion or gasification process.

- Properly manage and dispose of these residues to minimize environmental impacts and ensure safe handling.

- Energy Utilization and Distribution:

- Distribute the generated electricity to the grid or directly to consumers.

- Use the heat for district heating or industrial processes, improving overall energy efficiency.

- Monitoring and Maintenance:

- Continuously monitor the waste-to-biomass energy plant’s operations for efficiency and safety.

- Regularly maintain equipment to ensure reliable performance.

Environmental Considerations:

-

- Address potential environmental and health concerns associated with waste handling and emissions.

- Promote sustainable practices and adherence to environmental regulations.

Conclusion

The conversion of waste to biomass energy is a complex process that requires advanced technologies and careful management. Proper waste handling, emissions control, and resource management are essential to ensure the efficiency, environmental sustainability, and safety of waste-to-biomass energy plants.