Contact us for Engineering Services of Home Technology

Based on engineering design, experts in energy sectors, and CFD modeling we will provide the best design for home technology.

- Visit the website of CFD Flow Engineering.

- E-mail your query for technical support: hometechgrow@gmail.com, info@hometechgrow.com

Find The Best Technical Solutions

- Cost-effective Energy solutions using various biomass

- Affordable rate

- customized service for AC, air conditioning

- Best biomass solutions for your home and restaurant

Energy-efficient and cost-effective Biomass solution

- Based on science, engineering, and technology

- How can you use an LPG gas cylinder for more than 6 months

- How to select and install bio-mass, LPG gas stoves for homes and hotels

- How to clean exhaust air for big hotels

- How to save energy with low electricity bills

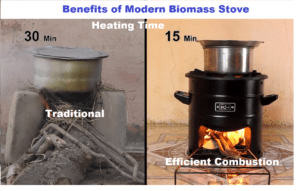

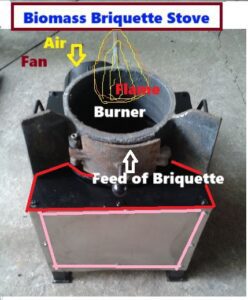

- We can help design and select Biomass briquette stoves for cooking as mentioned in the post

- The best biomass stoves in India like Chulha is a smokeless biomass stove developed by various industries ‘

- we can design to be more efficient and reduce indoor air pollution in rural areas in India as given in the post.

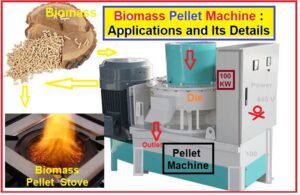

Engineering Solutions to Biomass Productions: Pellet and Briquette Industries

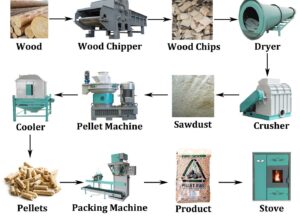

- Engineering plays a critical role in the production of biomass pellets and briquettes as mentioned, as it helps optimize the entire process, from raw material preparation to the final product.

- Our Efficient engineering solutions can enhance the productivity, quality, and sustainability of biomass pellet and briquette production, making these biofuels more competitive and environmentally friendly alternatives to fossil fuels

- We can provide cost-effective solutions engineering solutions and considerations for biomass pellet and briquette production:

Raw Material Preparation:

-

- Correct Sizing of biomass

- Drying methods of biomass

Pelletization Machines:

-

- Pellet Mills: Pellet mills are specialized machines that compress and shape biomass material into pellets. They come in various designs, including flat die and ring die pellet mills.

- Die and Roller Design: The design of the die and rollers in a pellet mill can impact pellet quality and production efficiency.

- Conditioning: Some materials may require preconditioning with steam or water to improve pellet quality.

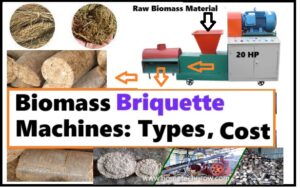

Gudilines for Briquetting Machines

-

- Briquetting Machines: These machines compact the biomass material into briquettes. They can be hydraulic, screw, or mechanical presses, depending on the material and production capacity.

- Binder Addition: Some materials benefit from the addition of binders to improve the binding and combustion characteristics of the briquettes.

Checking Quality Control:

-

- Sensors and Automation: Engineering solutions include the use of sensors and automation to monitor and control various parameters during production, such as temperature, moisture content, and pressure.

Heating and Cooling Problems:

-

- Cooling Systems: After production, pellets, and briquettes may need to be cooled to room temperature before packaging.

- Packaging Machinery: Automated packaging machinery can efficiently package the final product in bags or other containers.

Energy Efficiency Guarantee

-

- Engineering solutions should focus on optimizing energy usage throughout the production process.

- This can include efficient heating and cooling systems and the use of energy-efficient motors and controls.

- We can provide engineering combustion calculations for your final biomass products

Development Custome Biomass

-

- Ongoing research and development efforts should be an integral part of the engineering approach, aiming to improve the efficiency and sustainability of biomass pellet and briquette production.

Engineering Design and Ventilation for Hotel and Restaurant

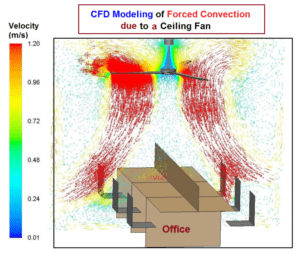

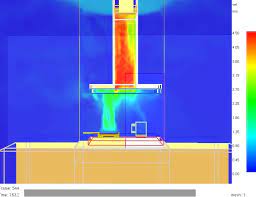

- Smoke and dust minimization techniques for briquette and pellet stoves based on CFD modeling will be consulted

- We provide engineering solutions to kitchen chimneys and ventilation based on CFD analysis

- How to select exhaust chimneys and fans for effective removal of flue gases in the home

- How to reduce the maintenance cost

- Location of kitchen chimney

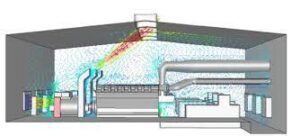

Advanced Design Analysis CFD Modeling of Heating and Ventilation

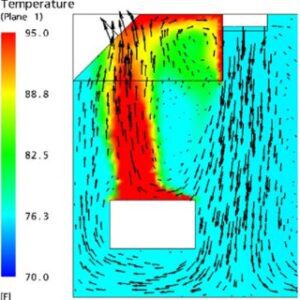

- Computational Fluid Dynamics (CFD) can be a powerful tool for designing ventilation systems for hotels and restaurants.

- CFD simulations allow engineers to model and analyze the airflow within a space, helping to optimize ventilation performance, ensure comfort, and maintain indoor air quality.

- CFD simulation can be effectively applied to the design and analysis of kitchen chimneys to ensure their optimal performance in removing cooking-related pollutants, heat, and odors from the kitchen space

- By using CFD simulations, engineers can gain valuable insights into the performance of kitchen chimneys, allowing for informed decisions and improvements in the design to enhance ventilation efficiency and maintain a healthy kitchen environment

Prediction of Airflow and Thermal Conditions:

-

- CFD software user to simulate airflow and thermal conditions within the hotel and restaurant.

- CFD simulations can provide insights into air distribution, temperature gradients, and potential areas of stagnation or discomfort.

- Evaluate the effectiveness of the ventilation system under different scenarios, such as peak occupancy or extreme outdoor conditions.

CFD Modelling office or hotel rooms

- Optimize Ventilation Design:

- Based on the simulation results, iterate and optimize the ventilation system design. Adjust parameters such as duct sizes, diffuser locations, and ventilation rates to achieve desired performance.

- Consider energy efficiency measures to minimize operational costs.

- Evaluate Air Quality:

- Assess indoor air quality by simulating the dispersion of contaminants and pollutants. Ensure that the ventilation system effectively removes or dilutes pollutants to maintain a healthy indoor environment.

- Consider Fire and Smoke Scenarios:

- Include simulations for fire and smoke scenarios to evaluate the effectiveness of the ventilation system in evacuating smoke and providing clear exit routes.

- Verify Compliance with Standards:

- Ensure that the ventilation system design complies with relevant building codes, standards, and regulations.

- Documentation and Reporting:

- Document the simulation setup, assumptions, and results. Prepare comprehensive reports to communicate the findings to stakeholders and regulatory authorities.

- By leveraging CFD for the design of ventilation systems, our experienced engineers can optimize performance, energy efficiency, and occupant comfort in hotel and restaurant spaces.

- It’s essential to collaborate with HVAC experts, architects, and other relevant professionals throughout the design process.