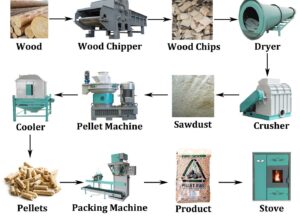

Process in Biomass Pellet Machine

- A biomass pellet machine, also known as a wood pellet machine or biomass pelletizer, is a piece of equipment used to convert biomass materials into compressed pellets.

- Biomass refers to organic materials derived from plants and animals, such as wood, crop residues, agricultural waste, and other organic materials.

The process of converting biomass into pellets involves several steps:

Raw Material Preparation

-

- The biomass materials need to be in a suitable size and moisture content for the pelletization process.

- Typically, the biomass is chipped, shredded, or crushed to a consistent size and then dried to the appropriate moisture level to ensure efficient pelletization.

Pelletization:

-

- The biomass pellet machine processes the prepared biomass through a series of mechanical actions. The machine compresses the biomass under high pressure and forces it through small holes in a die. This process creates dense and uniform biomass pellets.

Cooling and Screening:

-

- After pelletization, the hot pellets need to be cooled to room temperature to improve their durability and handling.

- The pellets then go through a screening process to remove any fines or undersized particles.

Pellet Packing:

- The final step is to pack the biomass pellets into bags or storage containers for distribution and use.

Types of Biomass for Making Pellets

- Biomass pellet machine has different pellet making process as per raw materials

- Biomass pellets can be made from a wide variety of organic materials. The choice of biomass depends on factors such as availability, cost, energy content, and the intended use of the pellets.

- Here are some common types of biomass used for making pellets:

- Wood:

- Wood is one of the most widely used biomass materials for pellet production.

- It includes various forms such as sawdust, wood chips, wood shavings, and wood residues from lumber mills and woodworking processes.

- Agricultural Residues:

- Crop residues and agricultural waste can be used as biomass for pellets. Examples include rice husks, straw, corn stover, sugarcane bagasse, peanut shells, and cotton stalks.

- Energy Crops:

- Certain fast-growing energy crops specifically grown for biomass production are used for pellets.

- Popular energy crops include switchgrass, miscanthus, and willow.

- Forestry Residues: Forest residues like tree branches, bark, and tops left after logging operations can be utilized as biomass for pelletization.

- Animal Waste: Animal manure and other organic wastes from livestock and poultry can also be processed into pellets, providing a means of waste disposal and a source of renewable energy.

- Food Waste: Certain types of food waste, such as fruit and vegetable peels or waste from food processing industries, can be used as biomass for pellet production.

- Algae: Algae can be cultivated and processed into biomass pellets, offering a potential source of renewable energy with lower land use requirements compared to other biomass sources.

- Industrial Waste: Various types of industrial waste, such as paper and pulp residues, can be used for pellet production, contributing to waste recycling and energy recovery.

- It’s important to note that the quality and energy content of biomass pellets can vary depending on the type of biomass used. For instance, wood pellets tend to have higher energy density and durability compared to some agricultural residues.

- Proper selection and preparation of the biomass material are essential to ensure the efficiency and performance of the pelletization process. Additionally, using sustainable and locally available biomass sources is crucial for promoting environmentally friendly pellet production practices.

Application of Biomass Pellet

Biomass pellets produced from machines have various applications, such as:

Residential Heating:

- Biomass pellets can be used in pellet stoves and boilers for residential heating, offering a renewable and environmentally friendly alternative to fossil fuels.

Industrial Heating:

- Biomass pellets can be utilized in industrial processes to provide heat for drying, processing, and other applications.

Power Generation:

- Biomass pellets can be co-fired with coal in power plants to reduce greenhouse gas emissions and promote the use of renewable energy sources.

- Animal Bedding: Biomass pellets can be used as animal bedding due to their absorbent and odor-reducing properties.

Biomass pellet machines play a crucial role in converting biomass waste into a valuable energy source, promoting sustainable practices and reducing greenhouse gas emissions.

Types of Biomass Pellet Machines

- There are two main types of biomass pellet machines based on their design and operation:

- flat die pellet machines

- ring die pellet machines.

- Let’s take a closer look at each type:

Flat Die Pellet Machine:

- Flat die pellet machines are usually smaller and more compact, making them ideal for small-scale or home use.

- They have a simple design and are easier to operate and maintain. The flat die is stationary, while the rollers rotate to force the biomass material through the die holes, forming the pellets.

- These machines are suitable for processing softer biomass materials like sawdust, straw, grass, and agricultural waste. They may have a lower production capacity compared to ring die pellet machines but are more cost-effective for small-scale applications.

Advantages of Flat Die Pellet Machines:

- Lower cost and affordable for small-scale production.

- Suitable for processing various biomass materials.

- Easy to operate and maintain

- Ideal for small-scale or home pellet production.

- Lower cost and maintenance compared to ring die pellet machines.

- Suitable for processing a wide range of biomass materials.

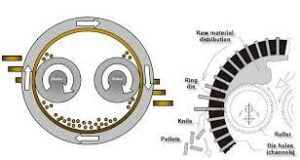

Ring Die Pellet Machine:

- The ring die pellet machine is designed for large-scale pellet production and is commonly used in industrial settings

- Ring die pellet machines are larger and more powerful, typically used for industrial-scale biomass pellet production.

- They have a more complex design with a rotating horizontal ring die and stationary rollers. The biomass material is forced through the die holes by the action of the rollers and the centrifugal force generated by the rotating ring die.

- Ring die pellet machines are capable of processing a wide range of biomass materials, including harder materials like wood chips, wood shavings, and other wood residues.

Advantages of Ring Die Pellet Machines:

- High production capacity, making it suitable for commercial and industrial use.

- Produces pellets with higher density and durability.

- More energy-efficient compared to flat die pellet machines for large-scale production.

Disadvantages of Ring Die Pellet Machines:

- Higher initial cost and maintenance compared to flat die pellet machines.

- Less versatile than flat die pellet machines, as some materials may not work well with the ring die design.

Cost of biomass Pellet Machine in India

- The cost of biomass pellet machines in India can vary depending on factors such as the production capacity, type of machine (flat die or ring die), brand, and additional features. Here are some approximate price ranges for biomass pellet machines in India as of my last update:

- Small-Scale Flat Die Pellet Machine:

- Prices for small-scale pellet machines in India could start from around ₹50,000 to ₹3,00,000 INR.

- Medium-Scale Flat Die Pellet Machine:

- For medium-scale production, with a capacity of around 500-2,000 kg/h, the cost may range from ₹3,00,000 to ₹10,00,000 INR.

- Large-Scale Ring Die Pellet Machine:

- Industrial-scale pellet machines with higher production capacities could cost ₹10,00,000 INR and above.

- The cost of a biomass pellet machine varies depending on the capacity, type, and manufacturer.

- The following are some factors that affect the cost of a biomass pellet machine:

-

- Capacity: The capacity of the machine is the amount of biomass that it can process per hour. The higher the capacity, the more expensive the machine will be.

- Type: There are two main types of biomass pellet machines: disc pellet machines and ring pellet machines. Disc pellet machines are more common and less expensive than ring pellet machines.

- Manufacturer: The cost of a biomass pellet machine also depends on the manufacturer. Some manufacturers are more expensive than others.

- In addition to the cost of the machine, there are other costs associated with starting a biomass pellet manufacturing business, such as the cost of raw materials, labor, and transportation.

- The total investment required to start a biomass pellet manufacturing business in India is typically around ₹ 30 lakh

Summary

- Both types of biomass pellet machines have their specific applications based on the scale of production, budget, and desired pellet quality.

- For small-scale and home use, a flat die pellet machine can be a cost-effective choice, while for large-scale industrial production, a ring die pellet machine is more suitable to meet the higher demand and produce pellets of superior quality and consistency.

1.Our Raw material is Bamboo

2. We want mechanised harvesting, mobile heavy duty chipper which will load chips into close trucks

3.dryer 4. Grinder

5. Flat die 500kg to 1000kgper hr

6.Ring die mill 2T, 5 T per hr

7.further cooling, पॅकिंग, weighing arrangement

8.pl give proven Technology Indian and imported suppliers

9.offers for above projects