Causes of Smokes in Biomass Stoves

- Smoke in biomass stoves is caused primarily by incomplete combustion of the biomass fuel.

- This happens when there isn’t enough oxygen or the combustion process is inefficient.

- Smokeless biomass solutions are designed to provide clean, efficient cooking and heating while reducing harmful emissions commonly associated with traditional biomass use.

- Here are the key causes of smoke in biomass stoves:

Incomplete Combustion

- Cause: When biomass doesn’t burn completely, it releases unburned particles and gases, creating smoke.

- Why It Happens:

- Lack of sufficient oxygen to fully burn the fuel.

- Poor airflow or air mixing inside the stove.

- Low combustion temperature that prevents the fuel from burning completely.

- Solution:

- Ensure adequate air supply and airflow in the stove.

- Use improved stove designs with better air-fuel mixing.

Wet or High-Moisture Biomass

- Cause: Wet or improperly dried biomass (wood, agricultural residues, etc.) produces more smoke because water vapor cools the combustion process.

- Why It Happens:

- Moisture in the biomass absorbs heat, lowering combustion temperature and resulting in incomplete burning.

- Solution:

- Use dry, well-seasoned biomass to ensure higher combustion efficiency and reduce smoke.

Low Combustion Temperature

- Cause: When the stove doesn’t reach a high enough temperature, the fuel doesn’t burn fully, leading to smoke production.

- Why It Happens:

- Poor insulation or design that fails to maintain a high combustion temperature.

- Starting a fire with insufficient kindling or fuel, leading to smoldering.

- Solution:

- Improve stove design for better insulation and heat retention.

- Ensure the fire is started and maintained at an optimal temperature.

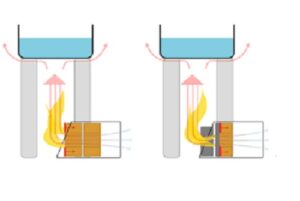

Poor Airflow Design

- Cause: Improper air circulation inside the stove leads to inefficient combustion and smoke.

- Why It Happens:

- Poor stove design where air doesn’t flow effectively around the fuel.

- Blocked air inlets or chimney outlets reducing oxygen supply.

- Solution:

- Clean air inlets and chimneys regularly to ensure proper airflow.

- Use stoves with good air channeling to allow better oxygen flow.

Fuel Overloading

- Cause: Adding too much fuel at once can smother the fire and reduce oxygen availability, leading to smoldering and smoke.

- Why It Happens:

- Overloading the stove with biomass prevents adequate airflow and cooling the fire.

- Solution:

- Add smaller amounts of fuel gradually, allowing for proper airflow and combustion.

Inappropriate Fuel Types

- Cause: Certain types of biomass (such as leaves, dung, or green wood) tend to produce more smoke than others.

- Why It Happens:

- High resin content or high moisture in certain biomass fuels leads to smoke production.

- Biomass types with lower calorific value don’t burn cleanly.

- Solution:

- Use dry, hardwood or densified biomass like pellets, which burn more cleanly and produce less smoke.

Poor Ventilation or Chimney Design

- Cause: Insufficient ventilation or poorly designed chimneys can lead to smoke being trapped inside the stove or room.

- Why It Happens:

- Short or blocked chimneys that don’t effectively vent smoke.

- Poorly designed chimney systems that don’t create enough draft to draw air through the stove.

- Solution:

- Ensure chimneys are properly designed to allow for good airflow and draft.

- Regularly clean chimneys to prevent blockages.

Uncontrolled Burning or Smoldering

- Cause: Uncontrolled burning or smoldering, where the fuel burns slowly without sufficient heat, results in excess smoke.

- Why It Happens:

- Adding large pieces of wood or fuel that smolder rather than burn rapidly.

- Stoves with no way to control the airflow or flame intensity.

- Solution:

- Use smaller, well-dried pieces of fuel.

- Opt for stoves with adjustable air control for regulating the burn rate.

Improper Starting of the Fire

- Cause: If the fire is started improperly (e.g., using damp materials or not providing enough oxygen), it can result in smoke before the fire stabilizes.

- Why It Happens:

- Using wet kindling or insufficient amounts of kindling material.

- Starting the fire with poor airflow, leading to smoldering rather than active burning.

- Solution:

- Start the fire with dry kindling and ensure proper airflow from the beginning.

10. Dirty or Clogged Stoves

- Cause: Accumulation of ash, soot, or residue in the stove or chimney blocks airflow, causing smoke to build up.

- Why It Happens:

- Uncleaned stove chambers or chimneys restrict airflow and cause poor combustion.

- Solution:

- Clean the stove and chimney regularly to remove blockages and ensure efficient operation

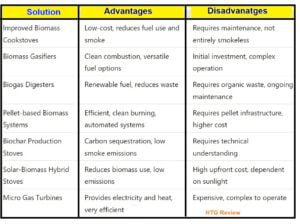

Improved Biomass Cookstoves

- How It Works: These stoves are designed to burn biomass (wood, crop residues, cow dung, etc.) more efficiently, producing more heat with less fuel and significantly reducing smoke emissions.

- Key Features:

- Improved Combustion Chambers: Maximizes heat transfer and ensures complete combustion, reducing smoke.

- Insulated Designs: Retain heat and burn fuel more efficiently.

- Air Circulation Systems: Allow for better air-fuel mixing, reducing incomplete combustion.

- Examples:

- Rocket Stoves: Use minimal fuel, channeling air through a small combustion chamber to produce high heat with little smoke.

- TLUD (Top-Lit UpDraft) Stoves: Gasify the biomass before burning, creating a clean flame with minimal smoke.

- Advantages:

- Reduces indoor air pollution.

- Uses less fuel, reducing deforestation and the burden of fuel collection.

- Affordable and easy to construct from local materials.

- Disadvantages:

- Requires maintenance and sometimes training for optimal use.

- Not completely smoke-free but significantly reduces emissions.

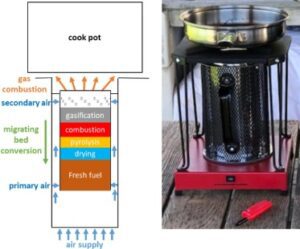

Biomass Gasification Systems

- How It Works:

- Biomass gasifiers convert solid biomass into a gas (syngas or producer gas) through a controlled process of heating the biomass in low-oxygen conditions.

- The gas is then used for cooking or heating.

- Best biomass stoves for homes

- Key Features:

- Syngas Generation: The biomass is converted into a combustible gas mixture that burns cleanly.

- Multi-Stage Combustion: Ensures minimal smoke and tar emissions.

- Examples:

- Community Gasifiers: Used for larger scale applications, such as in rural communities for centralized cooking or electricity generation.

- Small-scale Gasifiers: Portable units for household cooking.

- Advantages:

- Burns biomass cleanly with minimal emissions.

- Can utilize agricultural residues, wood chips, and other low-cost fuels.

- Disadvantages:

- Requires initial investment in equipment.

- More complex to operate compared to traditional stoves.

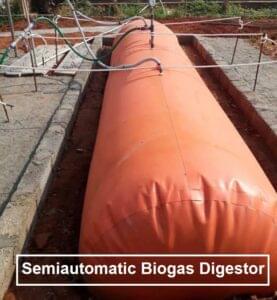

Biogas Digesters

- How It Works: Organic waste (animal manure, food waste, crop residues) is broken down anaerobically (in the absence of oxygen) in a digester, producing biogas (a mixture of methane and carbon dioxide) that can be used for cooking and heating.

- Key Features:

- Anaerobic Digestion: Produces methane gas from organic material.

- Biogas Burners: Specially designed burners use biogas for smokeless cooking.

- By-product: The slurry produced as a by-product is nutrient-rich and can be used as fertilizer.

- Advantages:

- Provides a renewable and smokeless cooking fuel.

- Reduces waste and produces valuable fertilizer.

- Suitable for rural households with access to livestock or organic waste.

- Disadvantages:

- Requires initial setup and ongoing maintenance.

- Not suitable for areas without access to organic waste.

Pellet-based Biomass Systems

- How It Works: Biomass pellets (compressed wood, agricultural waste) are burned in specially designed stoves or boilers that control air flow for clean, efficient combustion.

- Refer : Smoke and Dust Minimization Techniques for Briquette and Pellet Stoves

- Key Features:

- Pellets: Uniform, low-moisture biomass fuel that burns cleanly.

- Automatic Feed Systems: Some pellet stoves are equipped with automated fuel feeding systems, ensuring consistent burning.

- Efficient Combustion Chambers: Minimize emissions by optimizing heat transfer.

- Examples:

- Pellet Stoves: Used for household cooking and heating, offering cleaner combustion compared to loose biomass.

- Advantages:

- Highly efficient and low in smoke production.

- Reduces harmful emissions and indoor pollution.

- Disadvantages:

- Requires pellet production infrastructure.

- Can be more expensive than traditional biomass fuels.

Biochar Production Stoves

- How It Works: Biochar stoves are designed to create biochar (a form of charcoal) while cooking. The process captures much of the carbon in the biomass and converts it into biochar, with minimal smoke emissions.

- Key Features:

- Pyrolysis Process: Biomass is partially combusted in a low-oxygen environment to produce biochar.

- Clean Flame: Produces a clean, smokeless flame for cooking.

- By-product: Biochar can be used as a soil amendment to enhance agricultural productivity.

- Bio char Applications

- Advantages:

- Reduces greenhouse gas emissions by sequestering carbon in biochar.

- Provides a renewable and low-smoke cooking solution.

- Disadvantages:

- More complex technology and requires maintenance.

Solar-Biomass Hybrid Stoves

- How It Works:

- These stoves combine solar energy with biomass to cook food. Solar energy is used during the day, and biomass is used as a backup when sunlight is insufficient.

- Key Features:

- Solar Concentrators: Capture sunlight to cook food, reducing the amount of biomass needed.

- Biomass Backup: Efficient combustion chambers ensure smokeless operation when biomass is used.

- Advantages:

- Reduces reliance on biomass.

- Low emissions, making it ideal for environmentally conscious households.

- Disadvantages:

- Expensive initial investment.

- Requires sunny climates for optimal use.

Micro Gas Turbines (for electricity and heat)

- How It Works: Biomass can be converted into electricity and heat using micro gas turbines, which burn producer gas generated from biomass. This provides a smokeless source of energy for cooking, heating, and powering homes.

- Key Features:

- Electricity Generation: The system generates electricity while also producing heat for cooking.

- Clean Combustion: The gas turbine ensures that the producer gas is burned cleanly, without smoke.

- Advantages:

- Produces electricity and heat simultaneously, making it efficient.

- Ideal for off-grid homes with access to biomass.

- Disadvantages:

- High upfront cost.

- Requires technical expertise for operation and maintenance.

Conclusion

- Addressing the above causes can significantly reduce smoke production in biomass stoves, improving indoor air quality and stove efficiency.