Major Causes of Smokes from the Biomass Stoves

- High levels of smoke from biomass briquette stoves can be attributed to various factors related to combustion efficiency, fuel characteristics, and stove design.

- Identifying and addressing these causes is crucial for minimizing smoke emissions.

- Addressing the following factors through proper stove maintenance, biomass fuel preparation, and user education is essential for reducing smoke emissions from biomass briquette stoves.

- Regular inspections and adherence to best practices can significantly improve combustion efficiency and air quality.

- Here are some common reasons for high smoke production:

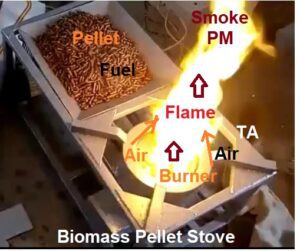

Incomplete Combustion:

- Incomplete combustion occurs when there is insufficient oxygen available for the combustion process.

- It can result from a lack of proper air intake or poor airflow within the combustion chamber.

Moisture Content in Briquettes:

- High moisture content in biomass briquettes hinders the combustion process.

- Wet or improperly dried briquettes can produce more smoke and less heat. It’s important to use well-dried briquettes with low moisture content.

Low-Quality Briquettes:

- Briquettes made from low-quality biomass materials, with inadequate binding agents or improper compression, may not burn efficiently.

- Choosing high-quality briquettes with the right composition is essential to reduce smoke emissions.

Incorrect Fuel Size:

- Using briquettes that are too large or too small for the stove’s combustion chamber can lead to inefficient burning and increased smoke production.

- Ensure the briquette size is suitable for the stove.

Poor Stove Design:

- Stoves with suboptimal designs, such as inadequate airflow pathways or poorly designed combustion chambers, can contribute to inefficient combustion and increased smoke.

- Selecting a stove with an efficient design is crucial.

Insufficient Preheating:

- Starting the stove with insufficient preheating or using cold fuel can contribute to incomplete combustion and smoke.

- Preheating the stove adequately before adding the main fuel helps establish a hot burn.

Airflow Restrictions:

- Blockages or restrictions in the air intake, exhaust system, or chimney can hinder proper airflow, leading to incomplete combustion and increased smoke.

- Regular cleaning and maintenance are necessary to prevent airflow issues.

Excessive Biomass Fuel Loading:

- Overloading the stove with too much biomass fuel can overwhelm the combustion process, resulting in incomplete burning and increased smoke production.

- Follow the manufacturer’s recommendations for proper fuel loading.

Operator Error:

- Lack of understanding or incorrect operation by users can contribute to inefficient combustion.

- Educating users on proper stove operation, including pellet fuel loading and air adjustment, is crucial to minimizing smoke emissions.

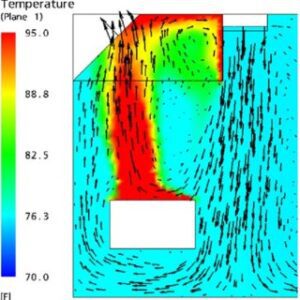

Poor Draft:

- An inadequate draft in the chimney or flue can affect the removal of combustion byproducts.

- Ensure that the chimney is properly designed and installed to promote good draft.

Altitude and Climate:

- Altitude and climate conditions can affect combustion efficiency.

- Adjustments may be needed in terms of air intake and fuel loading to account for variations in air density.

Improper Fuel Storage:

- Storing biomass briquettes in damp or humid conditions can increase their moisture content, leading to poor combustion and higher smoke emissions.

- Properly store briquettes in a dry environment.

Smoke and Dust Minimization Techniques

- Minimizing smoke and dust emissions from briquette and pellet stoves is essential for both environmental and health reasons.

- Many technological evolutions have been made to improve the quality of biomass fuel and stove design to reduce smoke with a lot of research.

- Some standard practices have been developed but these are not sufficient for many domestic and commercial applications

- Here are some techniques to achieve this:

Use High-Quality Biomass Fuel:

- Choose high-quality briquettes or pellets made from well-dried and compacted biomass materials.

- Low-quality fuels tend to produce more smoke and ash.

Proper Storage:

- Store biomass fuel in a dry and well-ventilated area to prevent moisture absorption, which can lead to increased smoke emissions during combustion.

Regular Maintenance:

- Keep the stove and flue clean by performing regular maintenance.

- Clean the ash pan and remove ash buildup from the burn chamber to maintain efficient combustion.

Optimal Airflow:

- Adjust the air intake controls on the stove to optimize airflow. Too much or too little air can affect combustion efficiency.

- Follow the manufacturer’s guidelines for proper air adjustment.

Correct Sizing:

- Ensure that the briquettes or pellets used are of the correct size for your stove.

- Using improperly sized fuel can lead to incomplete combustion and increased emissions.

Combustion Chamber Design:

- Choose stoves with well-designed combustion chambers that promote efficient burning and reduce the likelihood of smoke production.

Advanced Combustion Technologies:

- Consider stoves equipped with advanced combustion technologies, such as secondary combustion chambers or gasification systems.

- These features can enhance combustion efficiency and minimize emissions.

Moisture Content Control:

- Control the moisture content of the biomass fuel.

- Wet fuel can result in incomplete combustion, increased smoke, and higher emissions.

- Aim for a moisture content within the recommended range.

Use of Additives:

- Some additives or binders can be incorporated into the briquettes during the manufacturing process to improve combustion efficiency and reduce emissions.

Train and educate the Users:

- Provide clear instructions to users on the proper operation and maintenance of the stove.

- Users should understand the importance of using high-quality fuel, maintaining optimal airflow, and performing regular cleaning.

Install Adequate Ventilation:

- Ensure proper ventilation in the room where the stove is installed to minimize indoor air pollution.

- This can be achieved through well-designed ventilation systems.

Conclusions

- By implementing these techniques, you can minimize smoke and dust emissions from briquette and pellet stoves, promoting cleaner and more efficient

- Choose stoves that comply with emission standards and regulations.

- Look for certification labels to ensure that the stove meets environmental and safety requirements.