- CFD modeling of biomass stoves and kitchen chimneys involves the study and optimization of airflow, heat transfer, combustion, and emission dynamics to improve their performance, efficiency, and safety.

- Here’s a detailed breakdown of the scope and applications of CFD for these systems:

Table of Contents

ToggleBiomass Stoves

CFD can be used to design and optimize biomass stoves for cleaner and more efficient combustion.

a. Combustion Chamber Design

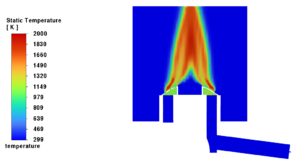

- Simulates the combustion process to optimize the chamber’s geometry for complete fuel combustion.

- Analyzes air-fuel mixing for improved burning efficiency.

- Identifies zones of incomplete combustion to minimize unburned hydrocarbons and carbon monoxide emissions.

b. Thermal Efficiency

- Predicts heat transfer from the flame to the cooking surface, ensuring maximum heat utilization.

- Optimizes the placement of heat exchangers or thermal shields.

Key areas include:

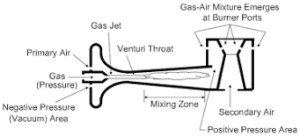

c. Airflow and Draft

- Models primary and secondary airflow to enhance combustion efficiency.

- Simulates natural or forced draft systems to ensure proper oxygen supply.

d. Emission Control

- Quantifies emissions such as CO, NOₓ, and particulate matter.

- Designs features like catalytic converters or particulate traps to reduce emissions.

-

Read Modern Smokeless Biomass Cooking Methods in kitchen

e. Material Optimization

- Evaluates heat stress and thermal gradients in stove materials to improve durability.

- Tests refractory linings and insulation materials to reduce heat loss.

Kitchen Chimneys

CFD plays a crucial role in the design and performance evaluation of kitchen chimneys to ensure efficient smoke extraction and improved indoor air quality.

a. Smoke Extraction

- Simulates the flow of flue gases and particulates through the chimney.

- Optimizes chimney geometry for faster removal of smoke and harmful gases.

b. Draft Efficiency

- Models natural and forced draft systems to maintain continuous airflow.

- Evaluates the effect of chimney height, diameter, and external wind conditions on draft performance.

c. Heat and Condensation Management

- Analyzes heat transfer through the chimney walls to prevent heat loss and condensation of vapors.

- Designs insulation layers or heat recovery systems for energy efficiency.

d. Backflow Prevention

- Studies reverse flow phenomena due to wind or pressure differences to prevent smoke from entering the kitchen.

- Optimizes cap designs or introduces flow rectifiers to prevent backflow.

e. Soot and Particle Deposition

- Models soot accumulation on chimney surfaces to design self-cleaning or low-maintenance systems.

- Simulates the behavior of particulate matter in different operational scenarios.

Combined Modeling: Biomass Stove and Kitchen Chimney

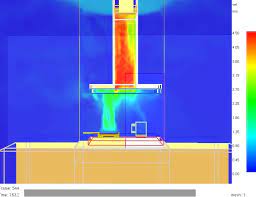

CFD can integrate the stove and chimney into a single simulation to ensure seamless operation.

a. Holistic System Analysis

- Evaluates the combined airflow and heat transfer from the stove to the chimney.

- Identifies bottlenecks that could lead to incomplete combustion or poor smoke removal.

b. Energy Optimization

- Designs systems for minimal energy loss between the stove and the chimney.

- Incorporates heat recovery units for preheating air or water.

c. Emission Pathways

- Tracks the flow of pollutants from the stove to the atmosphere to ensure safe dispersal.

- Evaluates chimney outlet designs to reduce environmental impact.

4. Practical Applications

- Domestic Use: Clean and efficient stoves for rural households using biomass fuels.

- Commercial Kitchens: Improved stove and chimney designs for hotels and restaurants using biomass.

- Industrial Kitchens: Large-scale systems for canteens or food processing units.

- Eco-friendly Cooking: Systems designed to meet emissions regulations and sustainability goals.

Benefits of CFD Modeling

- Reduced Design Time: Virtual testing accelerates product development.

- Cost Efficiency: Minimizes physical prototypes and trial-and-error testing.

- Improved User Experience: Optimizes heat delivery, reduces smoke leakage, and enhances safety.

- Sustainability: Supports cleaner combustion and reduced environmental impact.

Conclusion

CFD modeling of biomass stoves and kitchen chimneys is crucial for improving performance, efficiency, and environmental friendliness. It supports the development of systems tailored to specific needs, from rural households to commercial kitchens, ensuring cleaner and more sustainable cooking solutions.

Post Views: 367