Parameters to Evaluate the Performance of Biomass Stove?

Scope of Biomass Fuel

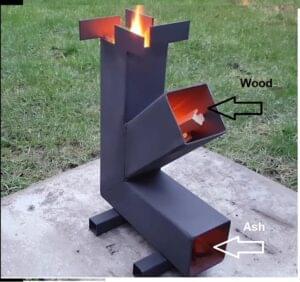

- Biomass fuel is widely used for cooking which is usually made from wood.

- A variety of biomass like wood chips or compressed pellets of sawdust and wood shavings. Some commonly used biomass are listed in the previous post.

- Biomass is less expensive per kWh than gas, electricity and oil. You can determine the cost of biomass fuel for briquette and pellet.

- The performance evaluation of a biomass stove is crucial for assessing its efficiency, environmental impact, and suitability for specific applications.

- It’s essential to conduct performance evaluations under controlled laboratory conditions as well as in real-world settings to get a comprehensive understanding of how a biomass stove performs.

- Additionally, standards and guidelines from organizations like the International Organization for Standardization (ISO) and the World Health Organization (WHO) can provide valuable frameworks for conducting these evaluations

- Here are some key parameters and methods used to evaluate the performance of biomass stoves:

Efficiency Calculations

- Efficiency is a critical parameter that measures how effectively the stove converts the energy in biomass fuel into useful heat.

- The efficiency of a biomass gas stove can vary depending on various factors, including the design of the stove

- Type of biomass gasification process used, and the operating conditions to determine the combustion efficiency

- Generally, biomass gas stoves can achieve efficiencies in the range of 50% to 80% or even higher under optimal conditions.

There are various ways to calculate efficiency, but the most common methods include:

Thermal Efficiency:

-

-

- This measures the percentage of heat produced compared to the energy content of the biomass fuel.

- It can be calculated by measuring the heat output and comparing it to the energy content of the fuel.

- Its formula is change in enthalpy of water : Q = m*C*ΔT

-

Combustion Efficiency:

-

- This measures how completely the fuel is burned. Incomplete combustion can lead to emissions of harmful pollutants. Combustion efficiency is often determined by measuring the concentrations of combustion gases like carbon monoxide (CO) and particulate matter.

- It is calculated as below

Combustion Efficiency (%) = [(Energy Released – Energy Lost) / Energy Released] × 100

- Energy Released

- Heat released represents the total energy released during the combustion of the biomass fuel.

- It is typically measured in joules (J), British thermal units (BTUs), or megajoules (MJ)

- Its value can be calculated based on the energy content of the fuel.

- Energy Lost:

- This refers to the energy that is lost as waste during the combustion process.

- It includes heat losses through incomplete combustion, radiative heat losses, convective heat losses,

- It also accounts other forms of energy that do not contribute to the desired output (e.g., cooking or heating)

Emissions and Air Quality in Kitchen

- Biomass stoves can produce emissions such as CO, particulate matter (PM), volatile organic compounds (VOCs), and greenhouse gases.

- It’s essential to evaluate these emissions to assess the environmental impact of the stove.

- Emission measurements can be done using specialized equipment like gas analyzers and particulate samplers.

Indoor Air Quality (IAQ)

- Biomass stoves can have a significant impact on indoor air quality.

- Monitoring indoor air pollutants such as CO, PM, and VOCs is essential to evaluate the stove’s impact on the health of users.

Environmental Impact:

- Consider the environmental impact of the stove over its lifecycle, including factors such as carbon emissions, deforestation (if applicable), and other sustainability considerations.

Fuel Consumption and Firing Rate

- Measuring the amount of biomass fuel consumed per unit of heat produced is another way to assess stove performance.

- This helps determine the stove’s fuel efficiency.

Cooking Performance:

- For stoves used in cooking applications, performance can be evaluated based on factors such as cooking time, fuel consumption per meal, and the quality of cooked food.

Cost and Maintenance

- Durability and Maintenance:

- Assessing the stove’s durability and ease of maintenance is crucial for long-term performance.

- This includes evaluating the lifespan of key components, like the combustion chamber and air supply mechanisms.

-

User Feedback:

- Gathering feedback from stove users can provide valuable insights into real-world performance. Users can provide information on ease of use, reliability, and overall satisfaction.

-

Cost-Benefit Analysis:

- Evaluate biomass stoves for cost-effectiveness of the stove, including the initial cost, fuel costs, and potential health and environmental benefits,

- It is essential for determining the overall performance of biomass stoves

-

Comparative Testing:

- Comparing the stove’s performance to other stoves on the market or against established standards can help provide context and assess its competitiveness.

Safety

- Assess the safety features of the stove, including protection against accidental burns, stability, and the risk of fuel spills or flare-ups.

How to Calculate the Efficiency of Biomass Stoves?

- Calculating the efficiency of a biomass stove involves measuring the heat output produced by the stove and comparing it to the energy content of the biomass fuel that was burned.

- Here’s a step-by-step guide on how to calculate the efficiency of a biomass stove:

Input Data

- Heat Output:

- Measure the heat output produced by the biomass stove. You can use a heat transfer fluid, such as water, and measure the temperature increase over a specific time period.

- The formula for calculating heat energy absorbed by water is given as below

Q = m*C*ΔT,

-

- where Q is the heat energy(KJ) , m is the mass of the fluid (Kg), C is the specific heat capacity of the water (fluid) , and ΔT is the change in temperature of fluid.

- Biomass Fuel Properties:

- Determine the energy content of the biomass fuel you used in the stove.

- You can find this information on the fuel’s packaging or in reference materials.

- It is typically expressed in joules (J), British thermal units (BTUs), or megajoules (MJ).

-

Firing Rate of Fuel

- Firing Rate of biomass Q = mass of biomass X Heating value +m *HHV

Calculate Heat Output:

- Calculate the heat output produced by the stove during the test.

- This is the amount of heat energy that was transferred to the heat transfer fluid.

- Use the following formula as below :

Heat Output, Q= mcΔT (J, BTUs, or MJ)

- Calculate Thermal Efficiency

Now, you can calculate the efficiency of the biomass stove using the following formula:

Efficiency (%) = (Heat Output / Energy Content of Fuel) x 100

-

- Convert the heat output to the same unit as the energy content of the fuel (e.g., if the energy content of the fuel is in MJ, ensure that the heat output is also in MJ).

- Divide the heat output by the energy content of the fuel and multiply by 100 to get the efficiency percentage.

Interpret the Results:

- The resulting percentage represents the efficiency of the biomass stove.

- For example, if you find that the heat output from the stove is4,000 MJ and the energy content of the biomass fuel is 10,000 MJ, the efficiency would be:

Thermal Efficiency = (4,000 MJ / 10,000 MJ) x 100 = 40%

- In this case, the biomass stove has an efficiency of 40%, meaning it effectively converts 40% of the energy in the biomass fuel into useful heat, while 60% is lost as waste.

Heat Losses from Biomass Stoves

Heat losses from biomass stoves refer to the energy that is not effectively transferred to the intended application (e.g., cooking or space heating) and is instead lost to the environment or as waste. Reducing these heat losses is crucial for improving the overall efficiency and performance of biomass stoves. Here are some common sources of heat losses from biomass stoves:

Incomplete Combustion:

- When biomass fuel does not burn completely, it results in the production of carbon monoxide (CO) and other incomplete combustion products.

- These gases carry away energy that could have been used for heating or cooking.

- To minimize incomplete combustion, stoves need proper design, air supply, and fuel quality control.

Radiative Heat Loss:

- Radiative heat loss occurs when heat is radiated away from the stove’s combustion chamber into the surroundings.

- Stoves can be designed with insulating materials and reflective surfaces to reduce this type of heat loss.

Convective Heat Loss:

- Convective heat loss happens when hot gases escape from the stove before transferring their heat to the intended application.

- Efficient stove designs include features to maximize heat transfer to the cooking surface or room while minimizing convective heat loss.

Exhaust Gas Heat Loss:

- The hot exhaust gases leaving the stove can carry a significant amount of heat.

- Stoves can be equipped with heat exchangers to capture some of this heat and transfer it back into the cooking area or room, improving efficiency.

Chimney Heat Loss:

- If the stove is connected to a chimney or flue, some heat may be lost up the chimney.

- Proper chimney design and insulation can help reduce this type of heat loss.

Heat Lost Through Cookware

- In cooking applications, the type and quality of cookware can impact heat transfer.

- Using well-fitting lids and cookware made of materials with good heat conductivity can help minimize heat losses.

Air Infiltration

- Air leaks around the stove or improper ventilation can lead to heat losses.

- Stoves should be installed correctly with proper seals and ventilation systems to prevent unwanted heat loss and ensure complete combustion.

Heat Lost During Ignition and Shutdown:

- The process of igniting the stove and shutting it down can result in heat losses.

- Efficient stoves are designed to minimize these losses during startup and shutdown phases.

Operational Factors

- How the stove is operated can also affect heat losses.

- Overloading the stove with too much fuel or using damp or oversized fuel can lead to inefficient combustion and increased heat losses.

Stove Maintenance:

- Neglecting stove maintenance, such as cleaning and inspecting components, can lead to reduced efficiency over time as soot and debris accumulate.

Scope of CFD Modeling for Biomass Stove

- Computational Fluid Dynamics (CFD) modeling has a significant scope and potential in the design, analysis, and optimization of biomass stoves.

- The scope of CFD modeling for biomass stoves is broad and encompasses various aspects of stove design, combustion processes, heat transfer, and emissions. Here are some of the key areas where CFD modeling can be applied to biomass stoves

- CFD simulations can provide valuable insights into the complex flow and heat transfer phenomena that occur within the stove, helping researchers and engineers improve stove performance, efficiency, and emissions reduction.

- Here’s an overview of the scope of CFD modeling for biomass stoves:

Design Optimization:

- CFD allows engineers to virtually prototype and optimize the design of biomass stoves before physical prototypes are built. This can significantly reduce development costs and time.

- Stove components, such as combustion chambers, air supply systems, and heat exchangers, can be analyzed and refined for better performance.

- Different geometries, materials, and configurations can be tested to find the most efficient and cost-effective design.

Combustion Efficiency:

- CFD modeling can simulate the combustion process in detail, helping to optimize air-fuel mixing, combustion rates, and combustion efficiency.

- It allows for the investigation of combustion parameters such as fuel particle size, moisture content, and fuel bed characteristics.

Heat Transfer Analysis:

- CFD can model heat transfer within the stove, helping to design heat exchangers or other heat recovery systems for efficient utilization of heat.

- It can be used to analyze how different materials and insulation affect heat retention within the stove.

Emissions Reduction:

- CFD simulations can help identify strategies to reduce emissions, such as carbon monoxide (CO) and particulate matter (PM), by optimizing combustion conditions and ensuring complete combustion.

- Understanding combustion chemistry through CFD can lead to cleaner and more efficient combustion.

Airflow Distribution

- CFD can analyze airflow patterns within the stove, ensuring that air is supplied efficiently to the combustion zone and distributed properly for even heating or cooking.

- It can also assess the impact of different ventilation strategies on stove performance and indoor air quality.

Transient Analysis:

- CFD can model transient conditions, allowing for the simulation of startup and shutdown processes, which can be critical for understanding stove behavior in real-world applications.

Scale-Up and Scaling Down:

- CFD modeling can assist in scaling up or down stove designs for different applications, from household stoves to larger community or industrial-scale stoves.

Sensitivity Analysis:

- Researchers can use CFD to conduct sensitivity analyses, exploring how changes in various parameters affect stove performance.

- This is valuable for understanding the robustness of stove designs.

Validation and Verification:

- CFD results can be validated and verified through comparison with experimental data, ensuring the accuracy and reliability of the simulations.

Prediction of Emissions

- CFD modeling can help assess the environmental impact of biomass stoves by predicting emissions and their dispersion, aiding in regulatory compliance and mitigation strategies.

Conclusion

- To obtain precise efficiency values, multiple tests under controlled conditions and the use of specialized equipment may be necessary.

- Additionally, consider using appropriate units for consistency and accuracy in your calculations.

Minimize heat losses

- To improve the overall efficiency of biomass stoves and minimize heat losses,

- Select the best quality of biomass with high heating value

- Choose well-designed stoves

- Operate the biomass stove correctly

- Perform regular maintenance like ash removal and cleaning

- Monitor the emissions

- Properly designed and maintained stoves can significantly reduce energy waste and minimize their environmental impact.

- For high thermal efficiency, there may be variations due to factors such as stove design, combustion efficiency, and measurement accuracy.

- Check testing and certification programs may help identify and promote more efficient stove models

CFD modeling of Biomass stoves

- It offers a powerful tool for the development and optimization of biomass stoves.

- It allows for detailed analysis of combustion, heat transfer, and fluid flow, which can lead to more efficient and environmentally friendly stove designs.

- However, it’s important to note that CFD modeling

- CFD results should be complemented with experimental testing to validate the simulations for real-world performance

Reference

- A. Kale et al, Design and Development of Biomass cook stoves at high altitude, 2022