Furnaces Used for Jaggery Plants

- Furnaces for jaggery production are essential for the efficient processing of sugarcane juice into jaggery.

- Here are some key points to consider when selecting or designing a furnace for this purpose:

1. Type of Furnace:

- Traditional Furnaces: Often made of bricks, these are commonly used in rural areas. They are relatively simple but can be inefficient and have high fuel consumption.

- Improved Furnaces: Modern designs often incorporate better insulation, air control, and fuel efficiency. Examples include smokeless chulhas or improved biomass furnaces.

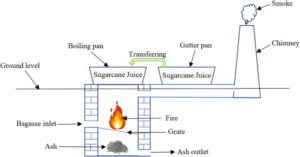

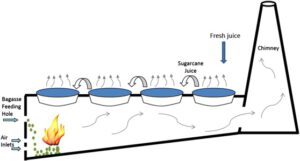

Parts of furnace for jaggery making

2. Fuel Type:

- Biomass: Commonly used in traditional furnaces, including bagasse (a byproduct of sugarcane), wood, or other agricultural waste.

- LPG or Natural Gas: Offers better control over temperature but may be more expensive.

- Electric Furnaces: Although less common, they provide precise temperature control and are more environmentally friendly.

3. Efficiency Considerations:

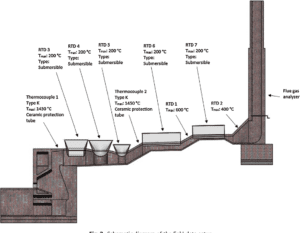

- Thermal Efficiency: Improved furnaces with better insulation and controlled air intake can significantly reduce fuel consumption and increase efficiency.

- Heat Distribution: A good furnace design ensures even heat distribution, which is critical for the consistent quality of jaggery.

- What is the efficiency of traditional jaggery making furnace?

- Conventionally jaggery is produced by evaporation of water in open pans. Furnace is fired using bagasse, which is residue of sugarcane, obtained during juice extraction.

- Furnace heat utilization efficiency is very low, which is ~20% for single, ~30% for two, and 35 to 40% for four pans.

4. Environmental Impact:

- Emissions: Modern furnaces are designed to minimize smoke and harmful emissions, which is important for both worker health and environmental protection.

- Waste Management: Some furnaces can also be designed to recycle or efficiently utilize waste products, such as using bagasse as fuel.

5. Cost and Scalability:

- Initial Investment vs. Long-Term Savings: While improved furnaces may have a higher initial cost, they can offer significant savings in fuel costs over time.

- Scalability: Depending on production needs, the furnace design can be scaled for small-scale or large-scale production.

Conclusion

- Selecting the right furnace for jaggery production depends on factors like the scale of production, available fuel types, and budget.

- An efficient and well-designed furnace can improve productivity, reduce costs, and produce higher-quality jaggery.

- Biomass furnaces represent a sustainable and cost-effective solution for jaggery production, particularly when designed and operated with efficiency and environmental considerations in mind.