Table of Contents

ToggleDesign of jaggery making plant

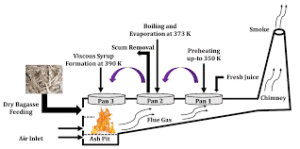

- Designing a jaggery making plant involves a detailed understanding of the process of converting sugarcane juice into jaggery, including extraction, clarification, boiling, molding, and packaging

- Here’s a breakdown of a typical jaggery making plant design suitable for small to medium-scale production (1–5 tons per day), including layout, equipment, and technical considerations

Process Flow for Jaggery Production

-

Sugarcane Feeding & Washing

-

Juice Extraction (Crusher/Mill)

-

Juice Filtration/Clarification

-

Boiling & Concentration (Furnace + Pan)

-

Molding/Cooling

-

Packaging & Storage

Plant Layout Design

A. Area Requirements (for ~2 TPD capacity):

-

Total: ~3000–5000 sq ft

-

Segmented into:

-

Sugarcane storage and feeding area

-

Crushing & juice collection

-

Boiling/furnace area (chimney + pan)

-

Cooling & molding platform

-

Storage & packing area

-

Fuel storage (biomass or bagasse)

-

Wastewater drainage system

-

Equipment and Machinery

| Section | Equipment | Description |

|---|---|---|

| Feeding | Conveyor or manual feeding | Optional automation |

| Extraction | 3-roller mill / crusher | Powered by motor or engine |

| Clarification | Juice tank, lime dosing | Settling tank for impurities |

| Boiling | Mild steel or SS pan (3-part or 4-part) | Direct heating by biomass, bagasse, or gas |

| Furnace | Brick or metal biomass furnace | With flue gas chimney |

| Cooling | Wooden/mild steel trays | Manual or semi-mechanized |

| Packaging | Molds, scales, wrapping | Manual or auto-packing |

Furnace Design

A good boiling furnace is key for fuel efficiency and smokeless operation.

Options:

-

Traditional chula (high fuel use, more pollution)

-

Improved biomass furnace (20–30% more efficient)

-

Bagasse-based system (saves cost if bagasse is used)

-

CFD-designed furnace (optional for high-end efficiency)

Fuel used: Bagasse, wood, or biomass briquettes.

Chimney and Ventilation

-

Chimney height: 25–30 ft (above roof level)

-

Diameter: 9–12 inches (for natural draft)

-

Should have:

-

Spark arrestor

-

Rain cap

-

Baffle plate (optional)

-

Design of Jaggery Furnace Using Biomass Pellets

The jaggery furnace is a crucial component in jaggery production, traditionally fueled by bagasse (sugarcane residue) or firewood. However, the adoption of biomass pellets as a fuel source enhances efficiency, sustainability, and reduces environmental impact.

1. Advantages of Using Biomass Pellets in Jaggery Furnace

- Higher Efficiency: Biomass pellets have a higher calorific value (3500-4500 kcal/kg) than bagasse, resulting in better combustion.

- Low Emissions: Produces less smoke, ash, and particulate matter, improving working conditions.

- Consistent Heat Supply: Uniform pellet size allows controlled combustion and steady heating, leading to better jaggery quality.

- Reduced Waste: Unlike bagasse, which contains moisture, pellets are dry and have higher energy conversion efficiency.

- Sustainability: Pellets are made from agricultural residues, sawdust, and other biomass waste, making them eco-friendly.

2. Design Features of a Biomass Pellet-Fired Jaggery Furnace

a) Furnace Structure

- Material: Built using fire-resistant bricks with insulation for heat retention.

- Dimensions: Designed based on capacity requirements, with a firebox to accommodate pellet-based combustion.

b) Combustion Chamber

- Equipped with a grate system for pellet feeding and controlled burning.

- Uses an air supply system (forced draft fans or blowers) to enhance combustion efficiency.

c) Fuel Feeding Mechanism

- Manual Feeding: Small-scale furnaces may use manual feeding of pellets.

- Automated Feeding: Larger units can have an automatic pellet feeder with a hopper, ensuring a continuous and controlled fuel supply.

d) Heat Transfer System

- Boiling Pans: Iron or stainless steel pans placed strategically over the fire chamber to ensure even heat distribution.

- Flue Gas Pathways: Designed to maximize heat utilization before gases exit through the chimney.

e) Chimney and Emission Control

- High-efficiency chimney for proper smoke exhaust.

- Cyclone dust collectors or wet scrubbers can be added to reduce particulate emissions.

3. Working Mechanism of Biomass Pellet Jaggery Furnace

- Pellet Feeding: Biomass pellets are fed into the combustion chamber either manually or automatically.

- Combustion Process: Air is supplied to ensure complete combustion, generating high heat.

- Heat Transfer: The heat is transferred to the boiling pans, where sugarcane juice is concentrated into jaggery.

- Exhaust & Heat Recovery: Waste heat is used to preheat air or juice, increasing overall efficiency.

- Jaggery Collection: Once the juice reaches the desired consistency, it is cooled and molded into jaggery blocks.

4. Efficiency and Performance Comparison

| Parameter | Traditional Bagasse Furnace | Biomass Pellet Furnace |

|---|---|---|

| Fuel Efficiency | ~20-30% | ~40-50% |

| Emissions | High smoke & CO₂ | Low smoke, eco-friendly |

| Heat Control | Inconsistent | Uniform, controlled |

| Maintenance | Frequent ash removal | Minimal ash formation |

| Fuel Availability | Seasonal (bagasse-dependent) | Year-round (pellets) |

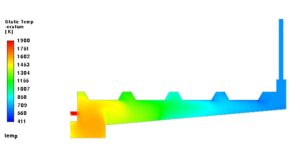

CFD Modeling for Design of Jaggery Furnace

- CFD Modeling for Design of Jaggery Furnace is an innovative and valuable approach to improve energy efficiency, optimize combustion, and reduce emissions during jaggery (gur) production.

- This process traditionally uses biomass or bagasse as fuel in rural setups, often with inefficient furnace designs.

Why Use CFD in Jaggery Furnace Design?

-

Optimize Furnace Geometry:

-

Analyze how furnace shape affects heat transfer.

-

Improve air-fuel mixing for better combustion.

-

-

Improve Thermal Efficiency:

-

Reduce fuel consumption by identifying heat losses.

-

Ensure uniform heat distribution for better sugarcane juice concentration.

-

-

Reduce Emissions:

-

Model flue gas composition and reduce CO, NOx, and unburned hydrocarbons.

-

-

Enhance Safety:

-

Analyze hotspots and prevent overheating.

-

-

Economic Benefits:

-

Lower operating costs by reducing fuel and enhancing output.

-

Key Aspects Modeled in CFD:

-

Combustion Modeling:

-

Biomass/bagasse combustion with proper air supply.

-

Models: Eddy Dissipation, Finite Rate, or Non-premixed combustion.

-

-

Heat Transfer:

-

Conduction through furnace walls.

-

Convection in flue gas flow.

-

Radiation modeling from flame and hot surfaces.

-

-

Fluid Flow:

-

Air and flue gas velocity distribution.

-

Draft behavior and chimney effect.

-

-

Pollutant Emission:

-

Soot, CO₂, CO, and NOₓ estimation.

-

-

Evaporation:

-

Simulation of juice concentration using energy balance.

-

Advantages Over Traditional Design:

| Traditional Approach | CFD-Based Approach |

|---|---|

| Trial-and-error design | Simulation-guided precision |

| High fuel use | Optimized combustion |

| Uneven heating | Uniform heat distribution |

| No emissions control | Emission analysis & reduction |

Conclusion

- A jaggery furnace using biomass pellets offers higher efficiency, cleaner combustion, and sustainable fuel utilization compared to traditional furnaces. Implementing automated feeding and air control systems further enhances productivity, making it a viable alternative for modern jaggery production.

- Would you like a 3D model or schematic diagram of the furnace design?

- CFD (Computational Fluid Dynamics) allows for virtual testing and optimization of these designs