Calculation of Kitchen Chimney Height for Effective Exhaust Flow

- Calculating chimney height for effective exhaust flow involves determining the necessary draft (pressure difference) to allow gases to rise and exit the chimney efficiently.

-

we need to Selection Kitchen Chimney for Clean Home : Types, Benefit and Installation

-

- The goal is to ensure that the exhaust gases are fully vented, maintaining good air quality and preventing smoke or harmful gases from lingering indoors.

Here’s a step-by-step approach to calculating chimney height for exhaust flow:

Key Factors Affecting Chimney Height

- Exhaust Flue Flow Rate (CFM): How much mass flow rate of exhaust gas needs to be vented.

- Flue Gas Temperature (T): Temperature of the gases inside the chimney.

- Ambient Air Temperature (T₀): Temperature of the outside air.

- Size Chimney (Diameter, D): Size of the chimney opening, which affects flow velocity.

- Stove and Type of Fuel in kitchen: Different fuels produce different volumes of exhaust gases.

- Draft Requirements: The natural or mechanical pressure needed to lift the exhaust gases.

Basic Formulas for Chimney Height

- The height of a chimney primarily depends on the draft created by the temperature difference between the hot exhaust gases and the cooler outside air.

- The draft pressure (ΔP) created by a chimney is given by:

ΔP=0.0342×H×(T−T0)/ To)

Where:

- ΔP: Draft pressure in inches of water column (inH₂O).

- H: Height of the chimney in feet.

- T: Temperature of the flue gases (in °F).

- T₀: Ambient temperature (in °F).

- 0.0342 is a constant that comes from the properties of air.

For proper exhaust, we need to create a sufficient draft to overcome resistance in the chimney system and to ensure efficient flow of gases.

Steps to Calculate Chimney Height for Exhaust Flow

1. Determine Exhaust Flow Rate

The flow rate depends on the size of the appliance, the amount of fuel burned, and the air required for combustion. Exhaust flow rate is often given in cubic feet per minute (CFM).

For example, assume the required exhaust flow is 500 CFM.

2. Calculate Required Draft Pressure (ΔP)

A typical draft requirement for a chimney is around 0.02–0.04 inches of water column (inH₂O). This depends on the system’s design and resistance.

Let’s assume we need 0.03 inH₂O of draft pressure.

3. Determine the Temperature Difference (ΔT)

Calculate the temperature difference between the flue gases and the outdoor air:

ΔT=T−T0

For example:

-

- T (flue gas temperature): 300°F (typical for wood-burning appliances).

- T₀ (outside air temperature): 60°F.

ΔT=300−60=240°F

Calculate the Minimum Chimney Height

Now, rearrange the draft formula to solve for H (chimney height):

H=ΔP/(0.0342×(ΔT/T0)) =

Plug in the known values:

- ΔP: 0.03 inH₂O.

- ΔT: 240°F.

- T₀: 60°F.

H=0.03/(0.0342×(240/60)

This value is clearly too low, so let’s consider the practical minimum height that also aligns with building codes.

Practical Considerations

- Even though the formula may give you a low theoretical value, practical chimney heights are typically around 10-15 feet minimum for residential use to ensure proper draft and avoid turbulence or backflow issues.

Chimney Height Based on Exhaust Flow Rate

- For exhaust flow calculations, we also consider the required height based on the volume of gases to be vented:

H=Flow × Constant/D^2

Where:

-

- Flow: Exhaust flow rate (in CFM).

- Constant: A factor (usually based on system design and fuel type).

- D: Diameter of the chimney.

- Example If the diameter is 6 inches (0.5 feet), and the exhaust flow rate is 500 CFM, and assuming a constant of 12 for wood-burning stoves:

H=500×12/0.5^2

This result is excessive, showing the need to re-adjust either flow rates or diameter, as a typical home chimney is usually between 10 to 20 feet.

Adjustments for Ventilation Systems

- If mechanical draft systems (e.g., fans) are used, you can reduce the chimney height by using a powered vent system to assist in exhausting the gases.

- In case of inadequate draft, increasing chimney diameter or using chimney liners can improve the flow.

Chimney Height and Building Codes

- Follow the 3-2-10 rule: The chimney should extend at least 3 feet above the highest point where it passes through the roof, and at least 2 feet higher than any part of the building within a 10-foot radius.

- Taller chimneys (typically 10-15 feet minimum) are generally recommended for better draft performance.

Example Calculation

If the chimney diameter is 6 inches and you need to vent 500 CFM at a gas temperature of 300°F with an outside temperature of 60°F, and you need 0.03 inH₂O draft:

- Required chimney height: 10-15 feet (adjusted to practical and code requirements).

Factors in Selection of Kitchen Chimney Design

- When selecting a kitchen chimney design, several factors should be considered to ensure it meets your needs effectively. These include:

- Suction Power:

- The chimney’s ability to suck out smoke, fumes, and odors is crucial.

- For Indian kitchens, a higher suction power (900 to 1200 m³/hr) is recommended due to heavy cooking styles like frying and tempering.

- Chimney Size:

- The size of the chimney should match the size of your kitchen and stove. Standard sizes are 60 cm and 90 cm, with the chimney’s width matching or exceeding the stove’s width for optimal smoke extraction.

- Suction Power:

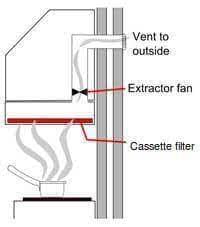

- Ducted vs. Ductless Chimneys:

- Ducted Chimneys: They remove smoke and fumes completely by expelling them outside the kitchen via a duct. They are more effective but require proper duct installation.

- Ductless Chimneys: These use filters to clean the air and recirculate it back into the kitchen. They are easier to install but less efficient than ducted systems.

- Filter Type:

- Baffle Filters: Ideal for Indian kitchens, as they effectively trap grease and require less frequent cleaning.

- Mesh Filters: Though affordable, they need frequent cleaning as they get clogged with grease easily.

- Charcoal Filters: Used in ductless chimneys to absorb odors, but they need regular replacement.

- Noise Level: Chimneys can be noisy due to their powerful motors. Choosing one with a noise level of around 58 dB or lower can ensure a quieter cooking experience.

- Mounting Style:

- Wall-Mounted Chimneys: Installed on the wall above the stove, suited for kitchens where the stove is near a wall.

- Island Chimneys: Suitable for stoves located in the center of the kitchen, mounted from the ceiling.

- Built-in Chimneys: These are integrated into the kitchen cabinets for a seamless look, good for compact kitchens.

- Design and Aesthetics: Sleek and modern designs can enhance the kitchen’s aesthetics. Look for chimneys that complement your kitchen decor, whether you’re going for a minimalist or a more elaborate look.

- Auto-Clean Features: Some chimneys come with auto-clean features that help in maintaining the chimney by automatically cleaning the filters, making maintenance easier.

- Budget: Kitchen chimneys come in various price ranges. A higher budget may get you advanced features like touch control, auto-clean, and better aesthetics.

- Energy Efficiency: Consider models that are energy-efficient, helping reduce power consumption, especially if used frequently.

- Warranty and After-Sales Service: It’s important to look for chimneys with a good warranty period and a reliable after-sales service network for maintenance and repairs.

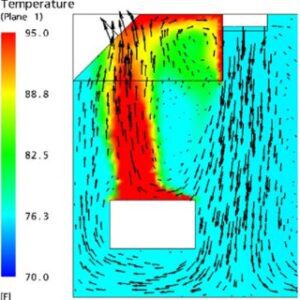

CFD for Checking of Chimney Draft and flow rate

- The scope of CFD in flue gas and chimney draft design is broad, providing precise simulations that improve the safety, efficiency, and environmental performance of chimney systems. By using CFD, designers can optimize every aspect of the chimney, from geometry to temperature profiles and flow dynamics, resulting in better overall draft performance.

Flue Gas Flow Dynamics

- Flow Velocity and Pattern:

- CFD can simulate the flow behavior of flue gases through the chimney, helping designers understand flow velocities, pressure distributions, and flow patterns.

- This allows for better sizing of the chimney to optimize ventilation.

- Turbulence and Eddy Formation: CFD models can predict turbulent flow and the formation of eddies that affect the efficiency of flue gas evacuation. By understanding these phenomena, engineers can design chimneys that minimize flow disruptions.

Pressure and Draft Optimization

- Pressure Drop: CFD helps assess pressure drops along the chimney length, which can influence the draft. By calculating these losses, designers can optimize the ventilation system to ensure efficient flue gas removal.

- Draft Simulation: CFD models are used to simulate the natural and forced draft systems that are essential for maintaining proper ventilation. This helps in determining chimney height and diameter for maintaining adequate draft pressure.

Temperature and Heat Transfer Analysis

- Thermal Gradients: CFD simulations provide detailed insights into temperature gradients inside the chimney, which is crucial for understanding the buoyancy effect that drives the natural draft. This helps in optimizing the flue gas flow for proper ventilation.

- Heat Loss Minimization: Chimney ventilation efficiency can be improved by analyzing and minimizing heat losses through the chimney walls. CFD helps evaluate different lining and insulation materials to retain heat and enhance flue gas buoyancy.

Chimney Design Optimization

- Geometry and Layout: CFD allows the analysis of different chimney geometries, including shapes (circular, rectangular) and heights, to optimize the ventilation flow. It helps in refining chimney cross-sections to improve exhaust flow and reduce resistance.

- Cap and Exhaust Design: The placement of chimney caps or exhaust fans can be optimized using CFD to prevent downdrafts or blockages while ensuring smooth gas flow.

Ventilation and Pollutant Dispersion

- Pollutant Concentration: CFD can simulate the dispersion of harmful gases (such as CO2, NOx, and particulates) as they exit the chimney, helping with environmental compliance and designing more effective emission control systems.

- Indoor Air Quality: For residential applications, CFD helps in preventing backflow of exhaust gases into living spaces, ensuring that flue gases are properly vented.

Wind and External Effects

- Wind Impact on Ventilation: External wind conditions can affect chimney ventilation. CFD can model the impact of varying wind directions and speeds on the flue gas flow, helping to design chimneys that perform well even under adverse weather conditions.

- Stack Effect and Buoyancy: CFD simulations help analyze how external temperature variations affect the stack effect, which drives natural ventilation in chimneys. It allows designers to account for seasonal changes and extreme weather conditions.

Applications of CFD in Chimney Ventilation

- Industrial Plants: For large-scale boilers and furnaces in power plants and factories, CFD helps optimize chimney ventilation systems for efficient pollutant removal and heat recovery.

- Residential Systems: In homes, CFD can be used to improve fireplace, stove, and boiler ventilation systems, ensuring safe and efficient operation.

- HVAC Systems: CFD models can assist in integrating chimney ventilation with heating, ventilation, and air conditioning (HVAC) systems to improve indoor air quality and energy efficiency.

Safety Considerations

-

- Preventing Backdraft: CFD simulations help detect potential risks of backdraft, where flue gases may re-enter the building. By modeling pressure differentials and airflows, designers can mitigate these risks.

- Fire Safety: Understanding the heat transfer dynamics through CFD can help in designing chimneys that prevent excessive heat buildup, reducing the risk of chimney fires.

Conclusion

- To calculate the proper chimney height for exhaust flow, start by determining the exhaust flow rate (CFM), the required draft pressure, and the temperature difference between exhaust gases and outside air.

- Then, apply the formulas to get a theoretical value but adjust according to practical guidelines like the 3-2-10 rule and building codes.

- A chimney height of 10 to 15 feet is typically required for effective draft in most home settings.

- The scope of CFD for chimney ventilation design is vast, offering precise tools to analyze flow dynamics, temperature distribution, and pollutant dispersion.

- By simulating real-world scenarios, CFD helps optimize the design and performance of chimney systems to ensure effective and efficient ventilation, while also complying with environmental regulations and safety standards.

Reference

- ASHRAE, 1996, Handbook- Systems and Equipment, Atlanta, GA.

-

Best Guides for Kitchen Chimney Installation and Service in Home