Major Issues in Drying of Food

Common Food Drying Methods

- Food drying solutions are used to preserve food by removing moisture, which inhibits the growth of bacteria, yeasts, and molds.

- There are several methods and technologies for food drying, depending on the type of food, energy source, and drying efficiency.

Sun Drying:

-

- Process: Food is spread out in direct sunlight to evaporate moisture.

- Advantages: Inexpensive and simple.

-

Read about the Sun Drying of Tomatoes for Food Preservation: Methods and applications

-

- Disadvantages: Depends on weather conditions, slow process, and can result in contamination by dust or insects.

sun drying of foods

Air Drying (Dehydration):

-

- Process: Uses a controlled environment with warm, dry air circulated over the food.

- Advantages: Faster than sun drying, better hygiene.

- Disadvantages: Requires energy for heating and air movement.

- Freeze Drying:

- Process: Food is frozen and then placed under vacuum, allowing moisture to sublimate directly from solid to gas.

- Advantages: Retains nutritional value, texture, and flavor.

- Disadvantages: Expensive equipment, time-consuming.

Electric oven drying of food

- Spray Drying:

- Process: Liquid food is sprayed into a hot air chamber, drying into a powder.

- Advantages: Suitable for liquids like milk or juice; quick process.

- Disadvantages: Requires specialized equipment, may not be suitable for solid foods.

- Drum Drying:

- Process: Food is spread over a rotating drum heated by steam, and the dried layer is scraped off.

- Advantages: Fast and efficient for purees or pastes.

- Disadvantages: Can affect texture and flavor, works for specific foods.

Microwave Drying:

-

-

- Process: Uses microwave radiation to heat food and evaporate moisture.

- Advantages: Rapid drying, minimal nutrient loss.

- Disadvantages: Requires specialized microwave dryers, may cause uneven drying.

microwave cooking or drying of food

-

Infrared Drying:

- Process: Infrared radiation penetrates food, causing water to evaporate.

- Advantages: Quick, energy-efficient, retains color and flavor.

- Disadvantages: Not suitable for all food types, risk of uneven heating.

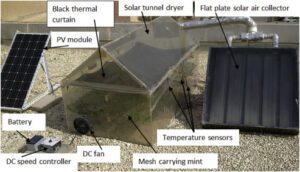

Solar Drying (Improved Sun Drying):

- Process: Uses solar collectors and fans to dry food in a more controlled manner.

- Advantages: Energy-efficient, faster than traditional sun drying, protected from contamination.

- Disadvantages: Requires sunny weather and setup.

Selection of Drying Method

The method depends on several factors:

- Type of food (fruits, vegetables, meat, liquid food, etc.).

- Desired quality (retention of nutrients, flavor, and texture).

- Cost and scale (household or industrial use).

- Energy availability (sun, electricity, or fossil fuels).

Are you interested in a specific method for home or commercial use?

Scope of CFD for food drying

- The scope of Computational Fluid Dynamics (CFD) for food drying is significant in optimizing drying processes, improving product quality, and increasing energy efficiency.

- Here’s how CFD can be applied:

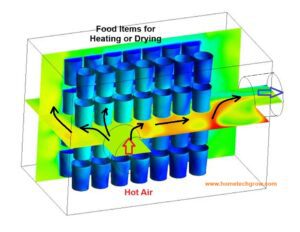

Optimization of Airflow and Heat Transfer

- Purpose: CFD can simulate how air and heat move within drying chambers. This helps to design more efficient dryers by ensuring uniform drying, minimizing hotspots, and optimizing drying time.

- Applications: Air drying, tray drying, and fluidized bed drying systems can be optimized for even moisture removal.

Energy Efficiency

- Purpose: By analyzing the thermal dynamics, CFD can be used to reduce energy consumption. It helps in identifying areas where energy is wasted, allowing for design improvements that reduce operational costs.

- Applications: CFD can be applied in the development of energy-efficient solar dryers, infrared dryers, and freeze dryers.

Product Quality Enhancement

- Purpose: CFD simulations can ensure that drying processes maintain the nutritional content, color, texture, and flavor of food. It can predict how different drying conditions (temperature, airflow, humidity) affect the final product quality.

- Applications: Used in fruit, vegetable, and meat drying to prevent over-drying or under-drying.

Dryer Design and Scale-up

- Purpose: CFD is crucial in designing and scaling up food dryers from lab-scale to industrial-scale operations. It helps in understanding how drying behavior changes with the size of the dryer and the food load.

- Applications: Fluidized bed dryers, spray dryers, and convective dryers benefit from CFD in large-scale operations.

Moisture Transport Modeling

- Purpose: CFD allows detailed modeling of moisture diffusion within food items, which is essential for accurate drying predictions.

- Applications: Used in freeze-drying and microwave drying where moisture transport significantly affects drying rates.

Environmental Control

- Purpose: CFD helps in controlling environmental conditions like humidity and temperature within the drying chamber. It can predict how external conditions impact the drying process and make real-time adjustments.

- Applications: Solar drying, where environmental factors like wind and solar intensity vary.

Reduction of Drying Time

- Purpose: CFD simulations help optimize drying time by determining the most efficient combination of airflow, temperature, and humidity.

- Applications: This is critical for industrial drying processes, where time savings lead to cost reductions.

Future Scope:

- Integration with Machine Learning: CFD combined with machine learning models can help predict drying outcomes more accurately and optimize control settings in real-time.

- Sustainable Drying Solutions: CFD can help develop more sustainable drying methods, such as solar or biomass-powered dryers, by optimizing airflow and energy distribution.

CFD’s ability to model complex fluid, heat, and mass transfer phenomena makes it an invaluable tool in enhancing food drying techniques